Supplier overview

Sandvik Coromant is a leading global supplier of metal machining tools, tooling solutions, services and know-how to the metalworking industry. It employs 8,000 people, has representatives in 150 countries, and introduces approximately 2,500 new products each year.

Sandvik Coromant, with a portfolio of 50,000 finished products and 2,500 new products released each year, invests twice as much in R&D as any other company in the industry - around 4% of total turnover.

A wide range of top-quality cutting tools is only half the battle. Equally important is the wealth of process and application knowledge we provide to help you get the most out of every purchase.

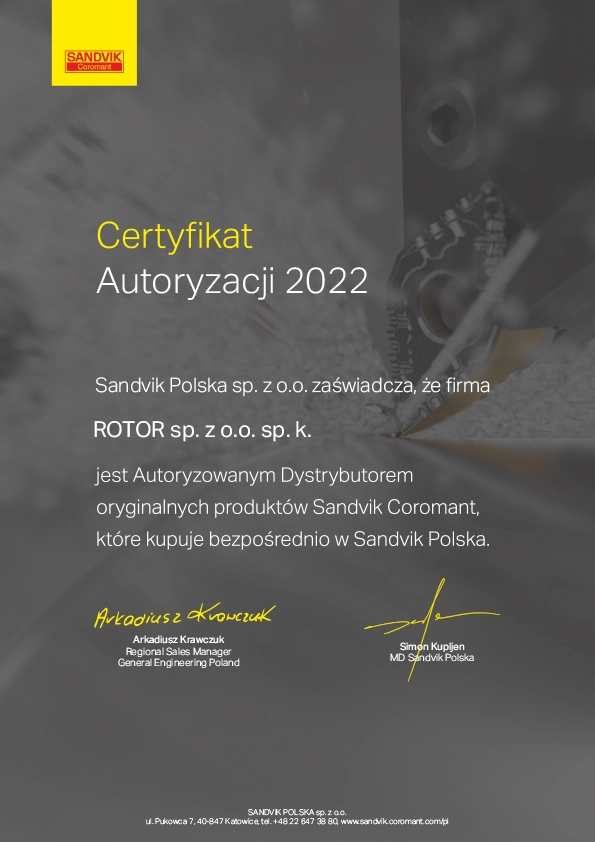

ROTOR Sp. z o. o. Sp. K. is an authorized partner with a high level of service, whose aim is to ensure significant savings in production costs. This comprehensive approach to the solution is tailored to the specific needs of industry groups and the manufactured component.

A range of Sandvik Coromant products available from the company ROTOR Sp. z o. o. Sp. K. includes the most popular items available from stock - most are delivered next day.

Product range

State-of-the-art design and advanced cutting materials - along with relevant application knowledge

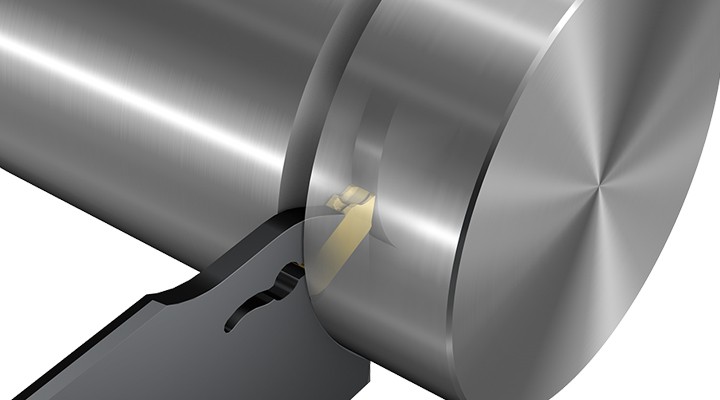

Turning tools

The combination of the best tool design, material quality and know-how allows you to reduce cost per part in virtually every turning operation.

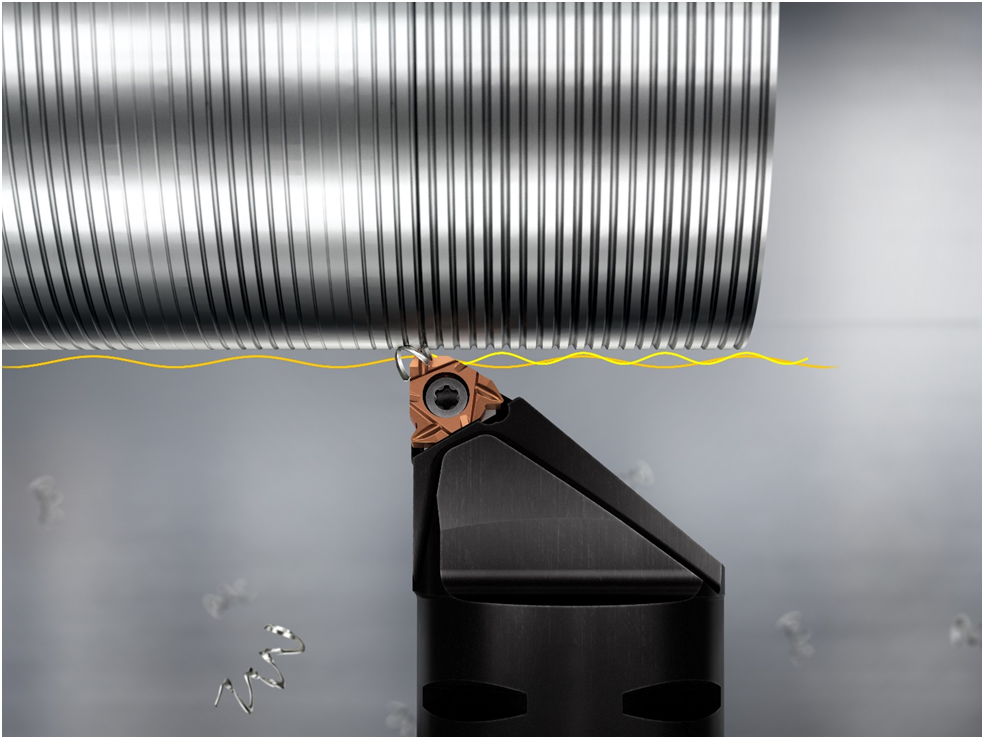

Tools for parting off and grooving

We guarantee tools that will provide chip control, surface finish and long cutting edge life.

Threading tools

A wide range of tools to suit different components, thread profiles and pitches, for both external and internal threads

Milling tools

From milling a flat surface to complex 3D shapes, there is a tool and insert combination that covers virtually any requirement.

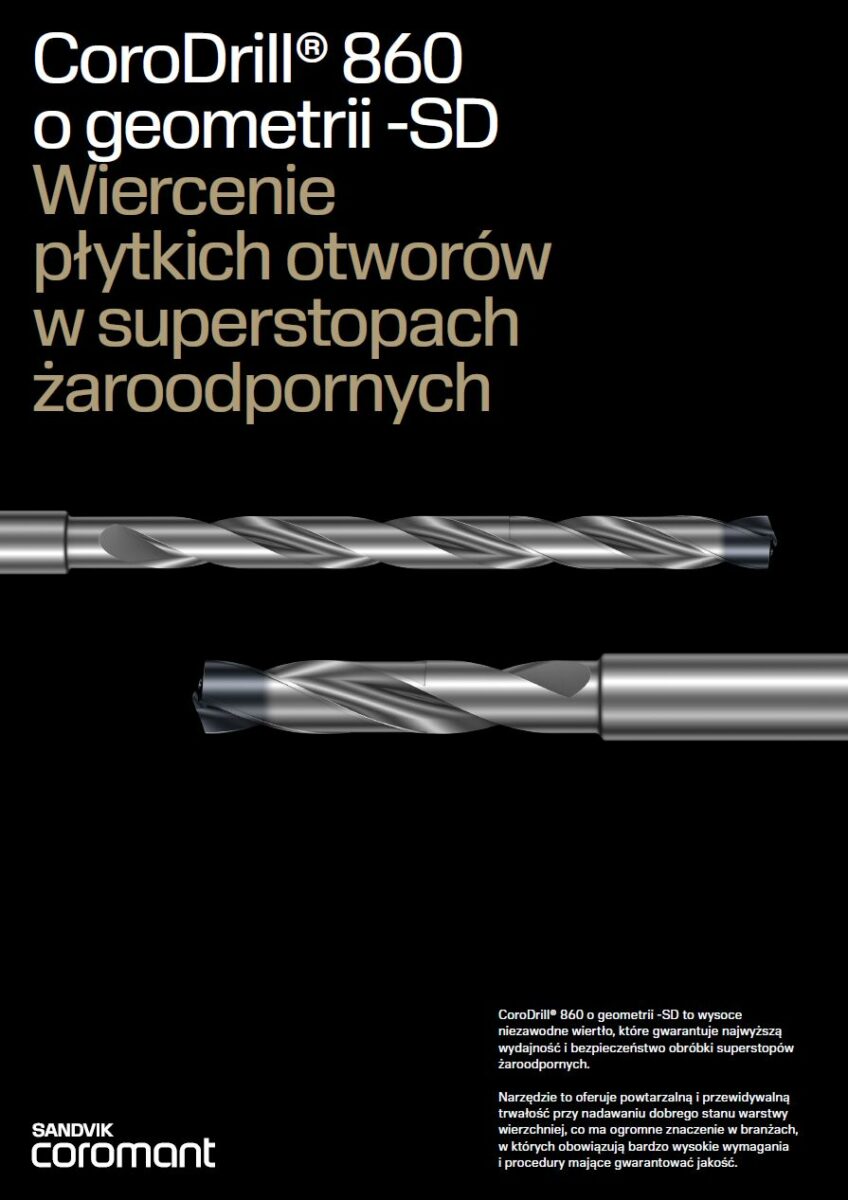

Drilling tools

Drilling often occurs at the last stage of the production cycle when component value is greatest - we design drills you can rely on.

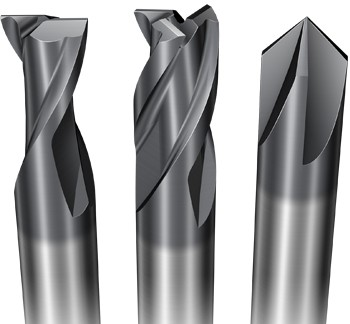

Monolithic tools

Top-quality, high-precision monolithic rotary tools for drilling, milling, threading, reaming and tapping.

Featured Products

Reliable parting and grooving

Top and bottom coolant provides chip control and long tool life. Easy coolant connection and insert replacement. User-friendly mounting with rail mounting for indexable insert. CoroCut QD Y-axis parting tools are designed with the insert seat rotated 90 degrees, resulting in more than sixfold increase in blade stiffness in Y-axis turning centers and multi-task machines.

Very rigid tool for external and internal threading. The iLock ™ coupling provides excellent stability and alignment accuracy when the insert is subjected to high cutting forces. Optimize your toolpath with CoroPlus® ToolPath, which includes OptiThreading ™ for better chip control.

Try CoroPlus® ToolPath during the one month trial period and see for yourself!

Versatile shoulder milling cutters with ramping capability, ideal for mixed production. CoroMill® 390 has a wide range of applications thanks to its comprehensive product range, including shoulder and long-edge cutters. These cutters are very suitable for 90 degree shoulder milling and are excellent for ramping and helical interpolation.

Uniform tools are used in a wide variety of applications. We offer, in particular, drilling with carbide drills, milling, threading with HSS tools, reaming and thread milling. Each monolithic tool has been designed to meet the requirements of high quality, precision and maximum efficiency, so that the machining process will be used to the maximum extent.

Interested in the offer?